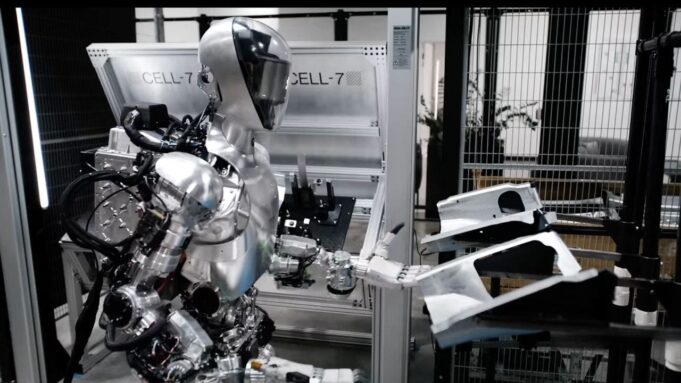

Almost six months after unveiling its collaboration with BMW, Figure’s sleek silver humanoid robot is showing remarkable advancements in its training for manufacturing roles. A newly published video showcases the robot’s growing abilities, underscoring the promising future of AI-driven humanoids in industrial contexts. This development represents a pivotal moment in the integration of sophisticated robotics into actual manufacturing settings.

SIGN UP FOR KURT’S NEWSLETTER FOR SECURITY ALERTS AND EXPERT TIPS – THE CYBERGUY REPORT HERE

Humanoid robot working in BMW assembly plant (Figure) (Kurt “CyberGuy” Knutsson)

The rise of AI-powered humanoid robots

The sector of AI-driven humanoid robots is currently witnessing a rapid development surge, with various companies striving to create adaptable machines capable of executing a broad spectrum of physical tasks conventionally handled by humans. These robots are designed to offer a more economical and reliable labor alternative, with the potential to transform economic growth and labor markets. The overarching objective is to establish a workforce that can adjust to diverse tasks, potentially separating economic expansion from population statistics and providing a labor source constrained solely by available resources.

Humanoid robot working in BMW assembly plant (Figure) (Kurt “CyberGuy” Knutsson)

CHINA UNVEILS ITS FIRST FULL-SIZE ELECTRIC RUNNING HUMANOID ROBOT

Figure’s humanoid: Key features and capabilities

Figure’s humanoid robot stands at 5 feet 6 inches tall, weighs around 132 pounds, and can handle a payload of up to 44 pounds. It is electrically powered and can operate continuously for five hours, reaching speeds of up to 2.7 mph. These features enable it to perform meaningful work in manufacturing settings while retaining a size similar to human workers.

Humanoid robot working in BMW assembly plant (Figure) (Kurt “CyberGuy” Knutsson)

ELECTRIC HUMANOID ROBOT POISED TO SHAKE UP THE JOB MARKET

BMW partnership: A milestone for Figure

The collaboration between Figure and BMW signifies a transformative milestone for the robotics startup. This partnership represents Figure’s first commercial agreement since its inception in 2022, reflecting the industry’s increasing appetite for humanoid robotic solutions.

The humanoid robots will be utilized at BMW’s manufacturing facility in Spartanburg, South Carolina, the largest automotive exporter in the U.S., employing 11,000 workers. Within the next 12 to 24 months, these robots will be integrated into various operations, such as the body shop, sheet metal fabrication, and warehouse functions.

Humanoid robot working in BMW assembly plant (Figure) (Kurt “CyberGuy” Knutsson)

HOW 1X’S HUMANOID ROBOT IS PUTTING A STOP TO YOU HAVING TO FOLD LAUNDRY

Training progress: The ‘BMW Full Use Case’

The latest video demonstration, named “BMW Full Use Case,” highlights the Figure robot’s advancements in several essential areas. The robot now exhibits enhanced skills in grasping intricate shapes, maneuvering around and dodging obstacles, accurately placing components, and even self-correcting errors.

For example, the robot has improved its ability to manage large, complicated shapes with its rubber-tipped fingers and can position them correctly on jigs, even when its view of the locating pegs is obstructed. When it detects that components are improperly aligned, it can nudge them into the right position with the back of its hand, demonstrating its ability to rectify mistakes autonomously.

Humanoid robot working in BMW assembly plant (Figure) (Kurt “CyberGuy” Knutsson)

Challenges and competition

Figure’s humanoid robot faces stiff competition, with several other entities developing parallel technologies. Apptronik, for instance, has collaborated with Mercedes to test its Apollo robot, while the veteran Boston Dynamics is still advancing its Atlas robot for various applications, including automotive manufacturing tasks. Tesla, leveraging its extensive car production facilities, is also competing with its Optimus robot.

Each corporation employs a slightly distinct approach to development and practical application, generating a varied and swiftly evolving environment in the humanoid robotics market.

HOW TO REMOVE YOUR PRIVATE DATA FROM THE INTERNET

Humanoid robot working in BMW assembly plant (Figure) (Kurt “CyberGuy” Knutsson)

The future of humanoid robots in manufacturing

As AI behavior models progress, we can anticipate substantial leaps in the capabilities of these humanoid robots. Their movements are expected to become faster and more fluid, and their skill acquisition process will likely quicken. The integration of these robots into tangible manufacturing environments is poised to increase, potentially reshaping production methods across diverse industries.

Nevertheless, it’s essential to examine the economic, ethical, and societal ramifications of the broad adoption of humanoid robots as we advance. The introduction of these sophisticated machines into the workforce prompts significant inquiries regarding the future of human employment, job displacement, and the necessity for new skills within the workforce. The forthcoming years will likely witness relentless, rapid developments in this sector, which could redefine our perception of work and automation. Striking a balance between technological progress and safeguarding human employment and well-being will be crucial as these innovations evolve.

Humanoid robot working in BMW assembly plant (Figure) (Kurt “CyberGuy” Knutsson)

Kurt’s key takeaways

The development of multifunctional humanoid robots stands to profoundly influence the manufacturing sector and beyond. Although Figure’s robot is in its initial phases, the advancements seen through the BMW partnership are encouraging and indicative of the swift progress being made in this field. Nonetheless, for these robots to genuinely transform the workforce, they must demonstrate a distinct economic benefit over human employees. This entails not only executing tasks effectively but also adjusting to new challenges and collaborating safely with humans.

What are your thoughts on how the widespread integration of humanoid robots in manufacturing and other sectors will affect the future of human workers in those environments? Share your views with us at Cyberguy.com/Contact.

For more of my tech insights and security notifications, subscribe to my free CyberGuy Report Newsletter at Cyberguy.com/Newsletter.

Have a question for Kurt or want us to explore specific topics?

Connect with Kurt on his social media channels:

Find answers to frequently asked CyberGuy inquiries:

Copyright 2024 CyberGuy.com. All rights reserved.